Join thousands of manufacturers

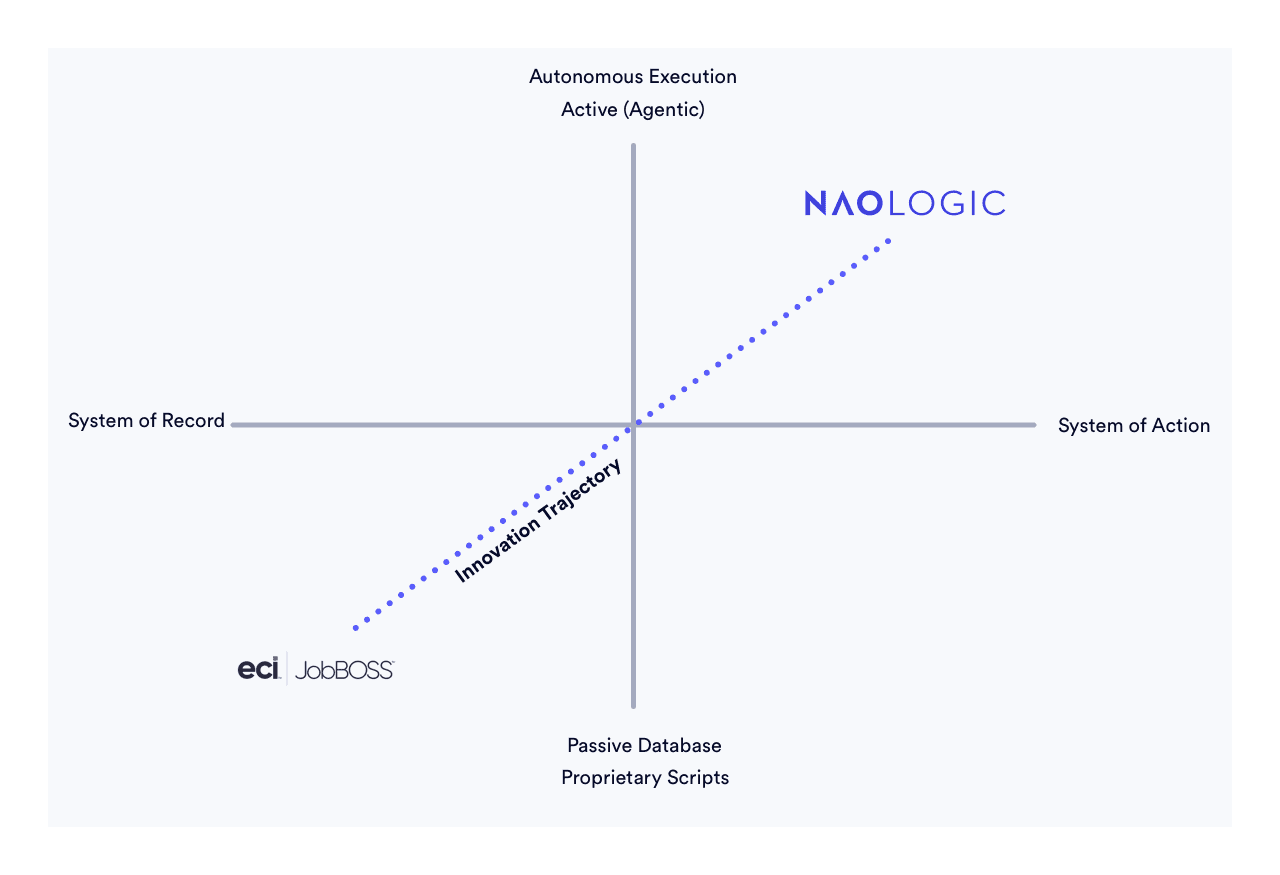

A direct comparison

JobBOSS shortcomings

Frustrations we hear from customers who migrated from JobBOSS to Naologic

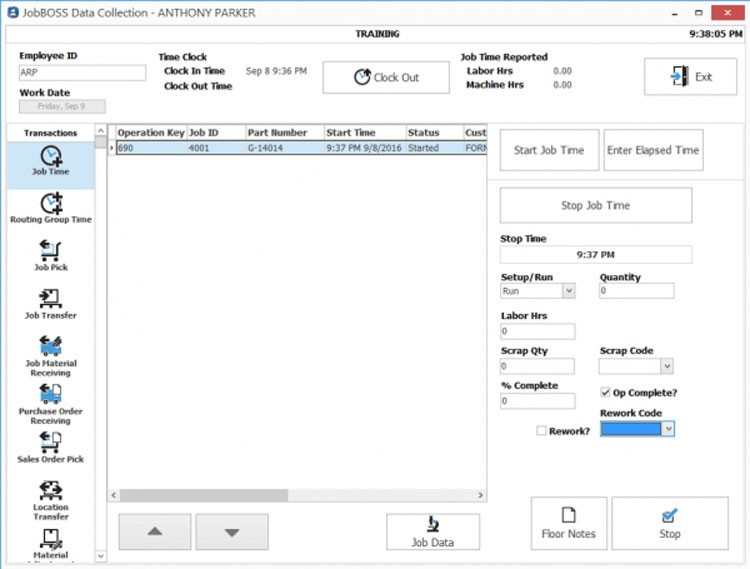

The "Nickel and Dime" Module Trap

Users are furious that the base JobBOSS software is practically an empty shell. Want to connect an outside app? Pay for the API module. Want operators to log time on the floor? Pay for the Data Collection module. It is a frustrating cycle of endless upselling.

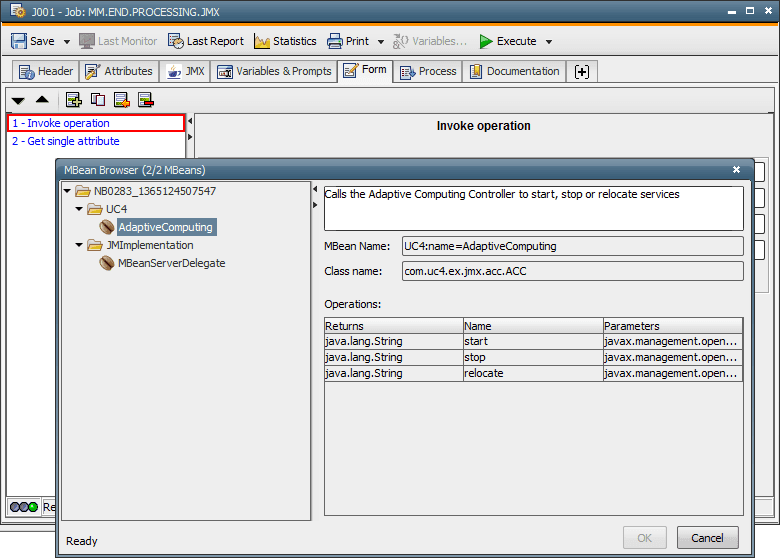

The Crystal Reports Nightmare

Extracting actionable business intelligence out of JobBOSS requires specialized knowledge of SAP Crystal Reports. Because the underlying database is bloated, building a custom report to simply see "profitability by machine" creates a massive bottleneck for the IT team.

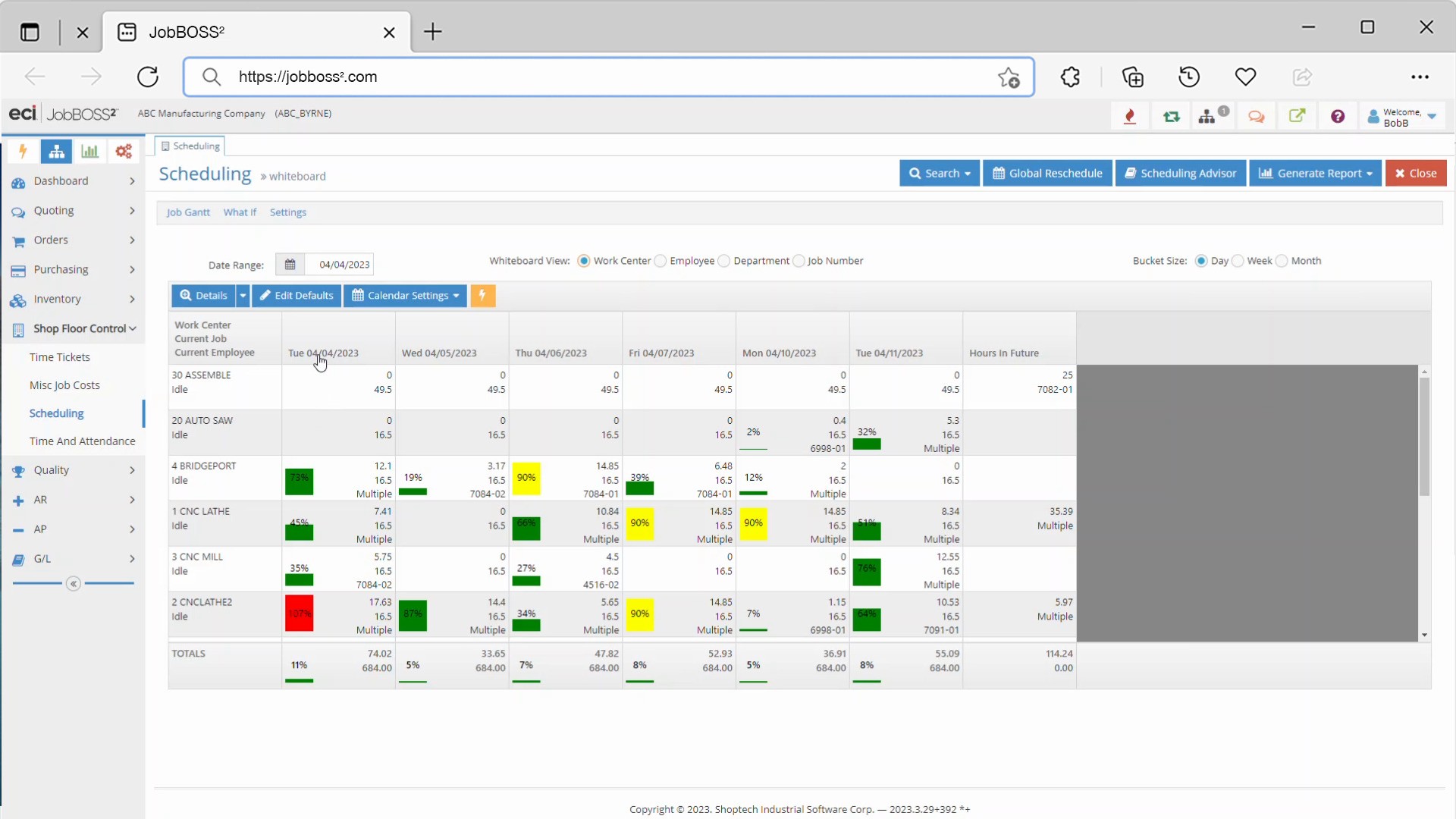

Rigid, Unusable Scheduling

The scheduling engine in JobBOSS requires absolute data perfection to function. Infinite scheduling creates impossible bottlenecks, and finite scheduling is so rigid that any real-world disruption requires hours of manual drag-and-drop adjustments to fix the Gantt chart.

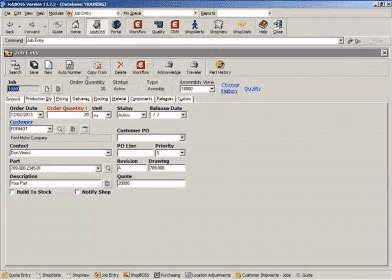

Clunky Interface

Even with the newer web updates, the core workflows remain incredibly click-heavy. Simple tasks require opening multiple overlapping tabs. Furthermore, their native accounting is weak, and their batch sync to QuickBooks is notorious for duplicating entries and dropping data.